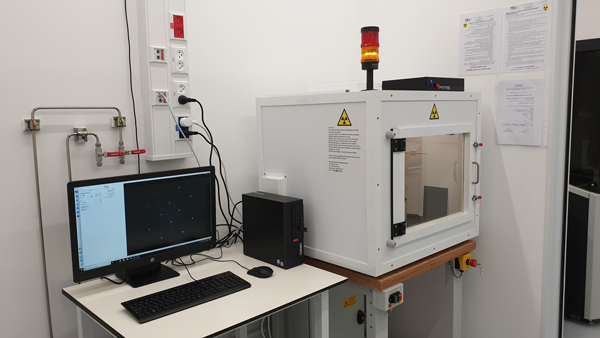

Complete system design and manufacture

PSEL are able to offer complete turnkey systems in addition to individual cameras and detectors, for those customers who require a complete solution for their imaging application. Technology offered covers the spectrum from Short Wave Infrared (SWIR) and visible light to X-ray and neutron detection.

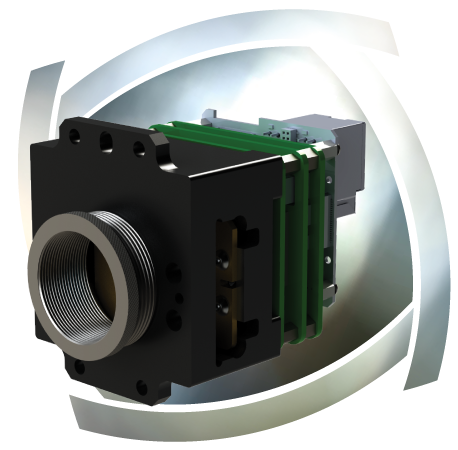

Field Programmable Gate Array (FPGA) Design

Developed and refined over the last three decades, the electronics team at PSEL have an extensive track record in the design of FPGA firmware for digital imaging applications.

Making the most of the latest devices, we have developed a strong expertise in the conception and implementation of high-speed image processing techniques. This is achieved by the use of both schematic capture and VHDL methodology to design, test and implement complex control and image processing algorithms. Tasks not requiring dedicated FPGA hardware, such as serial communication, are implemented using embedded processors also integrated within the FPGA design.

During the development process our designs are fully verified using industry standard methods. This means we can be confident of meeting strict timing and stability constraints resulting in reliable performance, even in the most demanding of applications.